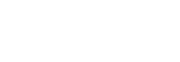

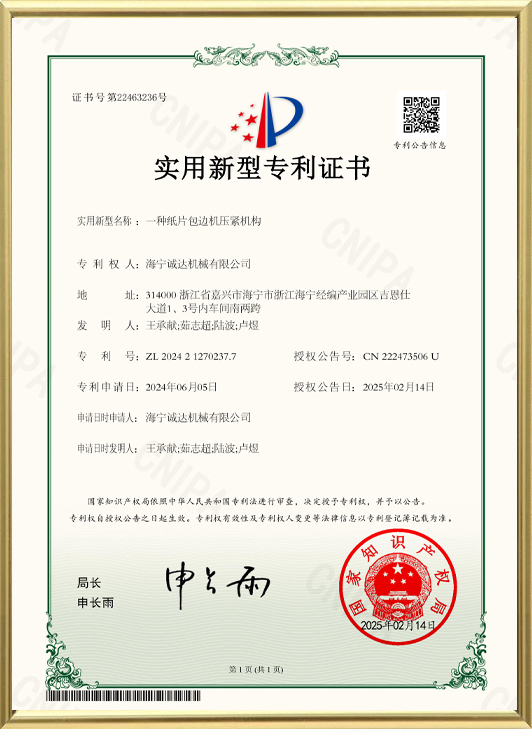

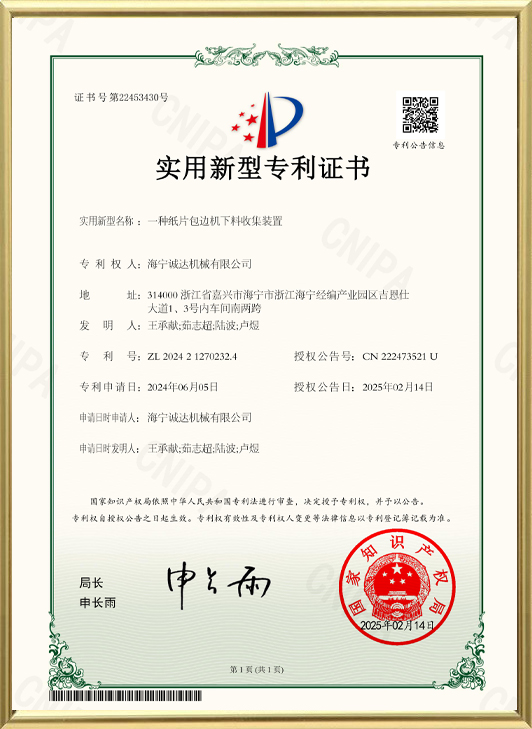

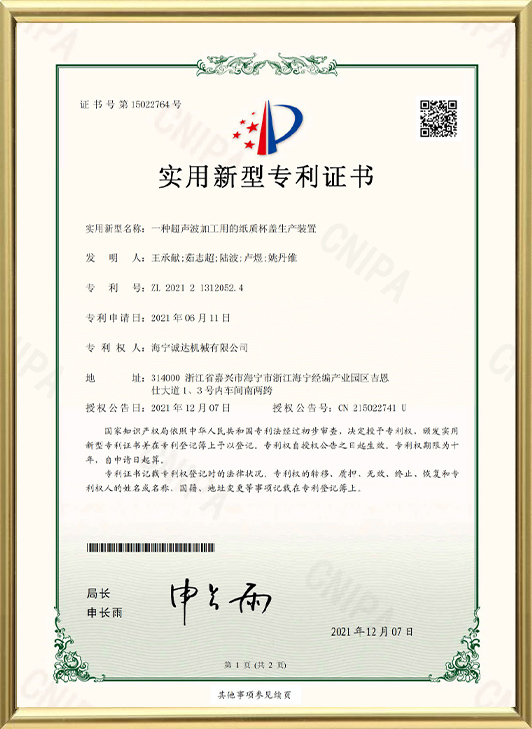

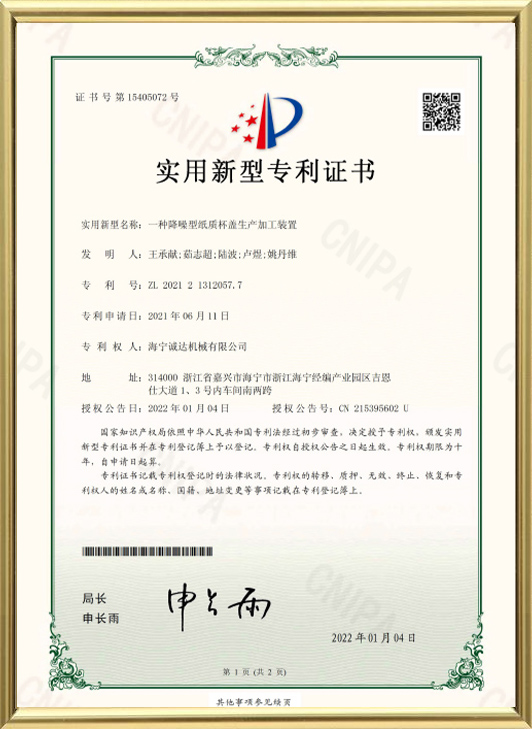

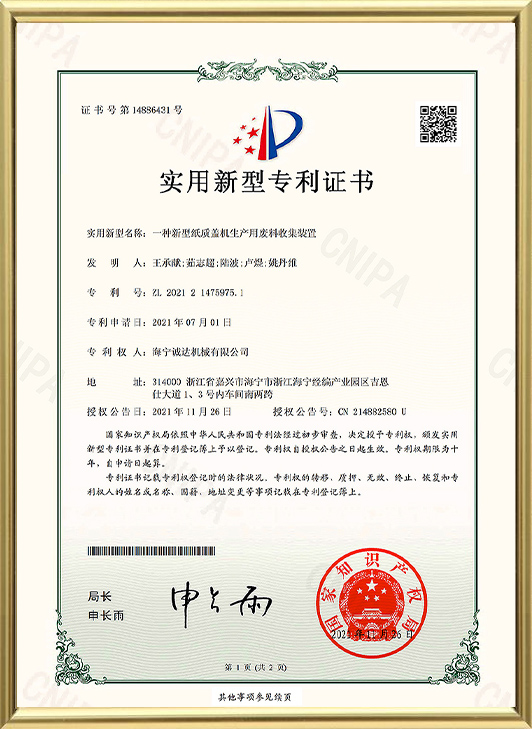

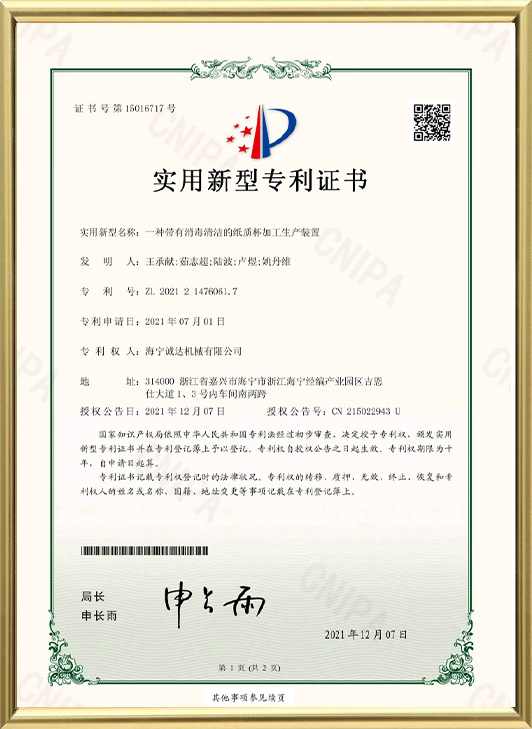

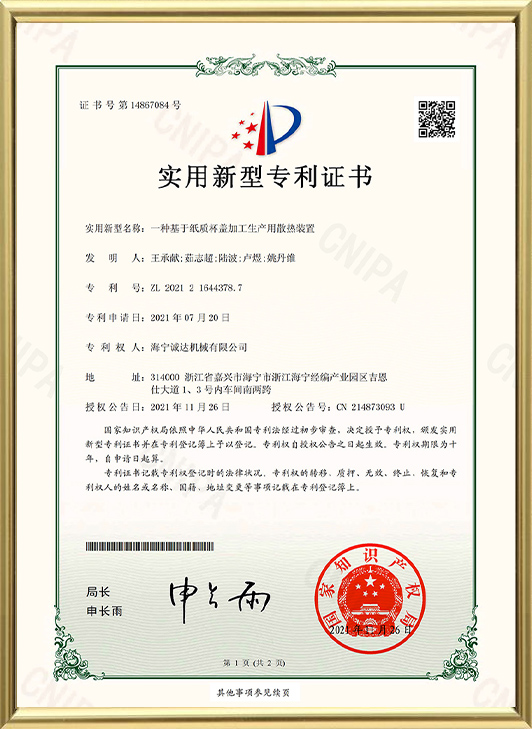

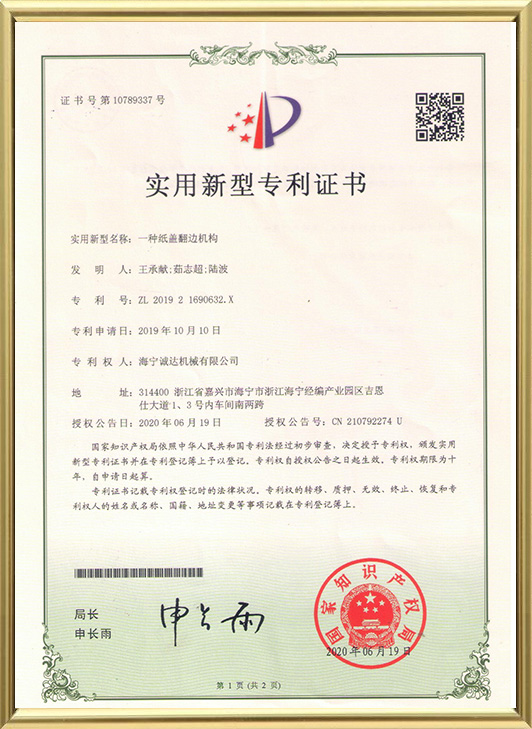

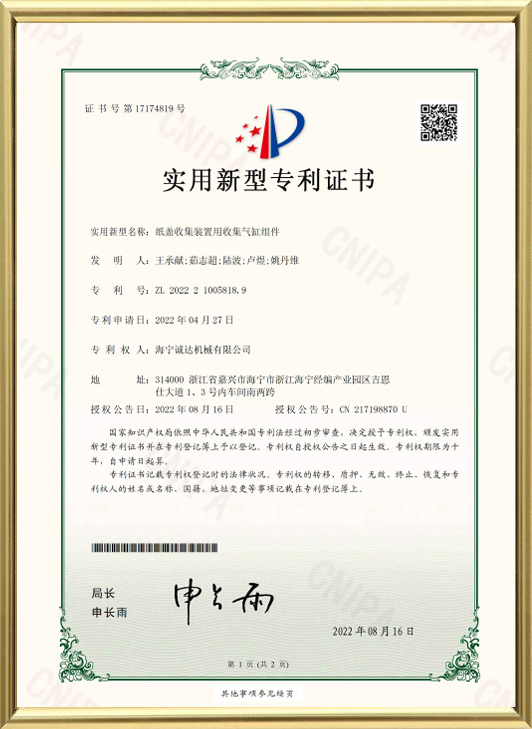

Anno MCMXCVIII conditum, Haining Chengda Machinery Co., Ltd. est professionalis Charta ore sgaque apparatus Venditores et Charta ore sgaque apparatus Societas. Habemus sectionem investigationis et progressionis (R&D), productionis et venditionis. Post viginti annos laboris assidui, societas nostra validam turmam technicam et centrum investigationis et progressionis habet, quod cum senioribus turmae technologiae formandi vascula chartacea Taiwanensis collaborat et patentes nationales, ut machinam tuborum rectorum, obtinet. Societas nostra officinas modernas compositionis, officinas processus partium praecisionis, centra institutionis, centra assecurationis qualitatis (QA), et aliam infrastructuram habet. Societas nostra systema certificationis CE et ISO9001, et iura nationalia importationis et exportationis habet.

Recentibus annis, fretus proprietatibus chartae Sinensis et progressu vasorum chartaceorum domi et in terris externis, seriem unitatum technologiae synchronizationis internationalis Machinae Fingendae Intelligentis cum systematibus detectionis automaticae et systematibus connexionis remotae pro machina poculorum chartaceorum, machina tuborum chartaceorum, machina operculorum chartaceorum, machina capsarum doner, et cetera, elaboravimus.

-

Quomodo potest ius frigidum bibere Calicem Elevare Potus Usus et Sustinebilitas?

Quomodo potest ius frigidum bibere Calicem Elevare Potus Usus et Sustinebilitas?Supra fundamentalem Function: Optimizing Cold Cup Design and Performance The Power of Structure: Mysterium Dupl...

-

How Does Provectus Automation Redefine Stackable Paper Lid Manufacturing?

How Does Provectus Automation Redefine Stackable Paper Lid Manufacturing?Inevitabilis Ortus Sustineri Packaging Solutions Aliqua mutatio globalis ad responsabilitatem environmental indust...

-

Quomodo potest PLM-60 Paper Lid Machine Revolutionize Your Production Line?

Quomodo potest PLM-60 Paper Lid Machine Revolutionize Your Production Line?Intellectus Operational Principia chartae Lid Machina The PLM-60 charta operculo machina in principi...

-

How Can Paper Blank Skiving Machines Revolutionize the Packaging Industry?

How Can Paper Blank Skiving Machines Revolutionize the Packaging Industry?Exploring Innovative Paper skiving Techniques for Sustainable Packaging Evolutio materiae et methodorum packaging ...

-

Quomodo provectus consilio augendae efficientiam et Vivacitas duplex murus charta calicem machina?

Quomodo provectus consilio augendae efficientiam et Vivacitas duplex murus charta calicem machina?I. Quomodo enim automatic Lubrication ensure stabilis mechanica operationem? In Duplex m...